The post Guide to Proactive Maintenance: What is it & How to Get Started appeared first on | eMaint.

What is Proactive Maintenance?

Proactive maintenance is a program that works to correct the root causes of failure and avoid breakdowns caused by underlying equipment conditions. Developing a proactive maintenance program helps organizations find hidden inefficiencies and “see the unseen.”

The proactive maintenance approach makes it possible to perform maintenance only when necessary based on maintenance data. More systematic elements of a maintenance program are addressed rather than machines themselves when organizations implement proactive maintenance. This program is key because organizations are empowered to:

Identify the Root Causes of Machine Failure

Resolve Problems Before They Become Failures

Extend the Life of Machinery and Reduce Downtime as a Result of Machine Failure

Collecting initial data, tracking ongoing trends and analyzing data to take action after fault indications are found are the cornerstones of proactive maintenance. Many proactive maintenance programs are supported by a CMMS/EAM, and there are a few approaches and keys to implementation success:

A focus on failure modes

Buy-in from leadership

Technologies selection

Skills enhancement

Proactive Maintenance vs. Reactive Maintenance

![]()

Even though Proactive Maintenance methods require more of an investment in time and money, the results are typically more cost effective, more efficient, and can extend the life of assets. This approach often reduces downtime, directly impacts overall productivity and company profitability. It is a more complex approach that works to solve problems at their root, helping to avoid machine wear and tear and the deterioration of the asset.

Where do Preventive and Predictive Maintenance fit in with Proactive Maintenance?

The best maintenance programs use a variety of maintenance methods to ensure the highest level of efficiency, cost-effectiveness and more. The top performing organizations typically have programs that are less than 10% reactive, between 25% and 35% preventive and between 45% and 55% predictive maintenance.

Predictive and preventive maintenance approaches work together to influence proactive maintenance, as it is more of an approach-based strategy rather than an individualized program for asset maintenance. A proactive maintenance plan can help make these programs operate more efficiently and limit some of the major expenses that can emerge from putting a plan into action.

How Much can You Benefit from Proactive Maintenance?

Critical equipment can fail at the worst time and rack up downtime, and drain a maintenance budget. With a mature maintenance program, organizations can identify potential faults before they disrupt service. This can mean dramatically reducing unplanned outages and associated costs. Although proactive maintenance requires in-depth planning, top level buy-in, investment and more, it ultimately helps organizations avoid over or under maintaining assets and offers a balance of costs, reliability, uptime, asset health and more.

To compete in the global marketplace, it is important for organizations to recognize the impact of maintenance on the business and customers. With a program that focuses on establishing, tracking and analyzing data on critical equipment, greater gains become possible. The unpredictability of reactive maintenance and breakdowns does not allow for improvements in key performance indicators, business drivers or the needs of a maintenance department.

How does Proactive Maintenance Work?

The transition to proactive maintenance can be a challenging one, with issues of culture change, budget, lack of training resources and full time employees to learn and perform analysis. There are are a few ways to help organizations get started, including:

Focusing on Failure Modes – Prioritization of plant systems and failure modes with impact on capacity and availability.

Receiving Buy-in from Leadership – Business decision of where to invest maintenance resources and technologies.

Technologies Selection – Infusion of available maintenance technologies with wireless capabilities.

Enhancing Employee Skillset – Increase in the core competency of the maintenance team.

3 Pillars to Successful Proactive Maintenance

The keys to successfully implementing a proactive maintenance program include methodical approaches to a new program start up plan, technology selection and data management.

1.New Program Start Up: It is critical to set a jump-off point and a vision for the future of the program. Best practices for organizations involve outlining goals, a start up plan, and identifying ways to achieve buy in from staff. Staff buy-in and acceptance can be found from demonstrating how the new program will make their jobs easier. With proactive maintenance, explaining how, with the power of tracking and leveraging data, technicians will not need to perform as many preventive maintenance tasks, and will have more time to focus on new initiatives.

Organizations looking to implement proactive maintenance can also perform a criticality survey and Failure mode and effects analysis (FMEA) and develop consulting support to ensure program success.

2. Technology Selection:Different assets require a mix of technologies, including mechanical, electrical and process. For example:

Screening tools – thermal imagers, oil analysis

Troubleshooting tools – electric testing, process tools

Diagnostic tools – vibration tester, corrective tools

3. Data Management: A key method to staying on track with goals is data management supported by a CMMS or SaaS software to support data capturing and analysis. With the data organization collected, organizations can monitor and track timely completion of critical work and impact on uptime.

Example Ideal Proactive Maintenance Workflow

![]()

For example, a proactive maintenance best practice workflow from baseline readings to analysis can look like:

Baseline with infrared cameras, quickly measure and compare height signatures of each piece of equipment on the inspection route, without disrupting operations

Monitor and measure bearing temperatures in large motors or other rotating equipment

Identify ‘hot spots’ on electronic equipment

Identify leaks in sealed vessels

Find faulty insulation in process pipes or other insulated processes

Find faulty terminations in high power electrical circuits

Locate overloaded circuit breakers in a power panel

Identify fuses at or near their current rated capacity

Identify problems in electrical switchgear

Capture process temperature readings

Trending with infrared cameras,the process includes:

Scheduling route based thermal measurements of all critical rotating equipment in order to capture overheating problems

Providing a detailed report of thermal images captured during regular preventive maintenance and review with the maintenance team

The advantage of this method includes avoiding costly downtime by:

Capturing ‘hot spots’ during regular PM routes

Extending the life of equipment

Eliminating a misdiagnoses

Integrate/upload thermal reports in data management software

Software allows to keep track of assets and review conditions over time

Analysis, which can be underscored by software to increase consistency across multiple team members, ensure more reliable data capture and decrease downtime spent on data collection. Best practices incorporate:

Use dashboards to compare against baseline and different types of measurements

All baselines and measurements saved to a central database

Proactive Maintenance Success Story

In a May 2017 poll among 600 leading companies across a variety of industries, 52% of attendees said they they used PM technologies a little, but wanted to do more with the data. A common theme among top companies today is a desire to incorporate more proactive maintenance. For example, PolyOne, a global provider of polymer-based materials and solutions, developed a standardized “global configuration” for their CMMS, and their Reliability Program (PRP) was rolled-out in five waves. A project timeline was established and included a week of PRP training, a site specific Lean Six Sigma/DMAIC PRP project, implementation of eMaint CMMS, all culminating into an overarching proactive maintenance program.

As a result, the company was awarded an Uptime Award for “Best Emerging Maintenance Reliability Program.” They also reached targeted maintenance expense reductions in the first full year of operation, a large part due to global transparency of parts inventory, and improved proactive approach to maintenance, producing a wave of preventive maintenance initiatives. Most importantly, for PolyOne customers the initiative has contributed to the company’s ongoing improvements in response time, reliability and quality.

To learn more about the importance of proactive maintenance, view our webinar on The Evolution of Proactive Maintenance.

Want More Maintenance & Reliability Content?

Sign up to stay up-to-date on our latest webinars, white papers and other industry content.

hbspt.forms.create({

portalId: '2250814',

formId: '32deb4ee-40bc-426c-8ddd-6b4a7c8794ed',

target: '#contact-resource-articles'

});

The post Guide to Proactive Maintenance: What is it & How to Get Started appeared first on | eMaint.

manage, it is critical that every location operates at peak performance. Schneider Electric specializes in the development of technologies to make energy safe, and provides project management services to help clients get their processes up and running.

manage, it is critical that every location operates at peak performance. Schneider Electric specializes in the development of technologies to make energy safe, and provides project management services to help clients get their processes up and running.

Fleet is one of the most important assets in a company, so it makes sense to improve the safety of your workers and maintain your equipment. eMaint offers

Fleet is one of the most important assets in a company, so it makes sense to improve the safety of your workers and maintain your equipment. eMaint offers  cturer in Turkey, specializing in custom ships, yachts, patrol boats and passenger ferries. ARES had so much success with eMaint

cturer in Turkey, specializing in custom ships, yachts, patrol boats and passenger ferries. ARES had so much success with eMaint  ed to be co-presenting “Keys To Plan and Implement a Successful Multi-Site CMMS Rollout” with client Nippon Sheet Glass, or NSG Group, at The Reliability Conference in Las Vegas, NV on April 26, 2017.

ed to be co-presenting “Keys To Plan and Implement a Successful Multi-Site CMMS Rollout” with client Nippon Sheet Glass, or NSG Group, at The Reliability Conference in Las Vegas, NV on April 26, 2017.

So, what have people been saying about the FREE Day of IIoT Exploration?

So, what have people been saying about the FREE Day of IIoT Exploration?

Cleveland Tubing, Inc. is a manufacturer of flexible, collapsible tubing products including FLEX-Drain and PumpFlex. The company set up eMaint so that meter readings on key indicators (temperature, pressure, fluid levels, suction) are imported and used to trigger priority work orders when work or inspection is needed based on predefined ranges.

Cleveland Tubing, Inc. is a manufacturer of flexible, collapsible tubing products including FLEX-Drain and PumpFlex. The company set up eMaint so that meter readings on key indicators (temperature, pressure, fluid levels, suction) are imported and used to trigger priority work orders when work or inspection is needed based on predefined ranges. Headquartered in South Africa, AFRIGRID offers a holistic approach to Infrastructure Asset Health Management, Predictive Maintenance and Infrastructure Asset Protection solutions. eMaint CMMS helps AFRIGRID keep up with maintenance and establish a historical record of the maintenance performed.

Headquartered in South Africa, AFRIGRID offers a holistic approach to Infrastructure Asset Health Management, Predictive Maintenance and Infrastructure Asset Protection solutions. eMaint CMMS helps AFRIGRID keep up with maintenance and establish a historical record of the maintenance performed.

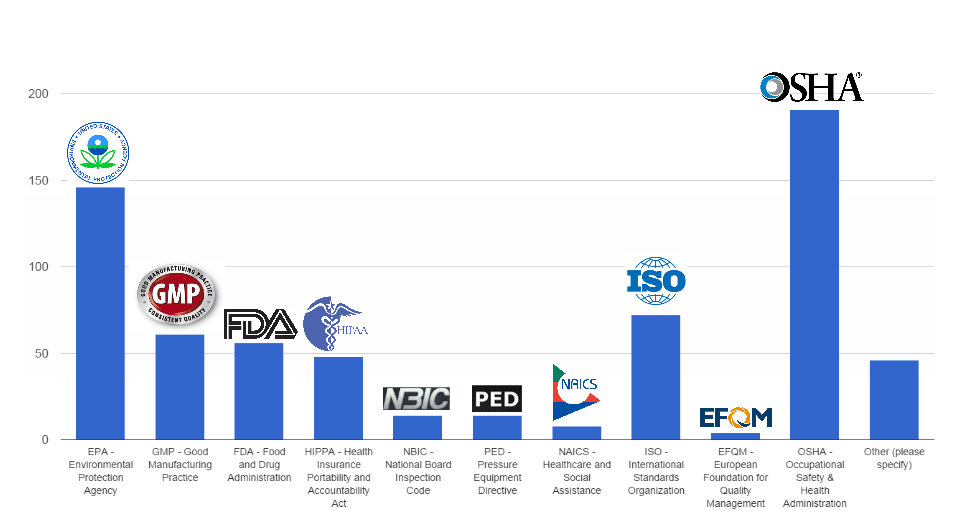

Organization across the world contend with OSHA, EPA, GMP, ISO or FDA every day. eMaint has helped thousands of organizations leverage their software to help ensure regulatory compliance. CMMS enables organizations to produce detailed documentation on work performed and charges on each asset and attach SOPs, instructions, LOTO and other safety documents to work orders. Additionally, organizations can capture the start and stop times of inspections, attach inspection instructions, and indicate if the inspection is a pass or fail.

Organization across the world contend with OSHA, EPA, GMP, ISO or FDA every day. eMaint has helped thousands of organizations leverage their software to help ensure regulatory compliance. CMMS enables organizations to produce detailed documentation on work performed and charges on each asset and attach SOPs, instructions, LOTO and other safety documents to work orders. Additionally, organizations can capture the start and stop times of inspections, attach inspection instructions, and indicate if the inspection is a pass or fail.